“Genetics are better, and our growth-enhancement tools are better, and we know a lot more about them,” Robbi Pritchard said, noting the term “precision ag” is typically reserved for row-crop discussions. It doesn’t have to be.

The Matching Game

Technology, economics and consumers dictate cattle feeding.

Cattle have changed. If your management hasn’t, animal scientist Robbi Pritchard suggests you take a look to be sure it’s still relevant.

The South Dakota State University professor addressed cattle feeders and allied industry at the Feeding Quality Forum in August.

“Genetics are better, and our growth-enhancement tools are better, and we know a lot more about them,” Pritchard said, noting the term “precision ag” is typically reserved for row-crop discussions. It doesn’t have to be.

“We could go that way in the cattle business, and we could make big strides,” he said.

That means matching cattle type to technology and ration.

“If they’re coming out of 1,600-pound (lb.) cows, they probably don’t need any implants,” the ruminant nutritionist said. “The DNA was there. The implants just fill in for a lack of DNA.”

Using those growth promotants in an animal with high growth potential will give you a “nitro-burning car that flames out. It’s not a good thing.”

However, another class of cattle would benefit from the technology, as a single implant can add 75 lb. of carcass weight.

“All we need to do is match up stage of growth, potency of the implant and caloric intake,” he said. “We’re getting much better at using our implants like scalpels instead of axes.”

The critical window is from weaning to 65% of their harvest weight.

“That’s where you change the percent Choice, that’s where you change what they weigh when they hit a Yield Grade (YG) 4,” Pritchard said. “These cattle have higher growth potential than they used to have, so we have to feed to that higher growth potential.”

He suggested only grazing commodity cattle on wheat and low-quality forage.

“Five to eight months of age: that’s the window where I can manipulate where I’ll be on quality grade, relative to yield grade in the end,” Pritchard said. “If I rough them too much during backgrounding — either with cornstalks or dormant prairie, I’m going to give up marbling.”

In a normal year, early weaning makes sense only for larger-framed cattle.

“Early weaning is going to make them fatter,” he said. “It will make them grade really well, but you’re going to hang up 100 lb. less carcass weight; it won’t pay.”

Weighing cost vs. later return, he said, “Creep-feeding fits best just within the nutritional gaps.”

Ranch-level changes have created more uniformity in supplies to the feedyard. For example, calving groups are tighter.

“We no longer need time for things to average out as we did when management wasn’t nearly as good. Time solved a lot of problems,” he said.

When are cattle ready?

Genetics play a big role in knowing when cattle are done, and those have changed.

When Pritchard’s great-grandfather trailed cattle to the railroad, they were usually driving 4-year-olds. “It took a really good steer to go to town when it was 3,” he said.

What rules marketing decisions today? Some sell when they’re “fat enough,” and some farmer-feeders sell when the corn is gone. As calf-replacement costs have escalated, some consider them finished one week before the packer won’t take them any longer or when the implant is wearing out.

“None of these are really sound, long-term plans,” Pritchard said. So, don’t listen to yesterday’s wisdom.

“We all learned in school: When cattle get fat, they get less efficient,” he said. “I believed in it a lot once upon a time.”

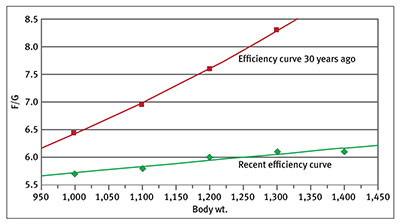

At the beginning of his career, feed-to-gain ratios on heavy cattle were 8.5 lb. to 1 lb. of gain. Today’s data? “Feed conversion barely got over 6 pounds on pens of cattle that got a pile of [Yield Grade 4s],” he said (see Fig. 1).

“What is my definition of done supposed to be? When I make the most money, or when I make the right product?” he asked, alluding to outside factors.

Much larger carcasses cause challenges at the packer level, where their infrastructure isn’t set up for the sheer size of some of today’s animals.

“They’re going to slow down our rate of change,” Pritchard said. “They’re a governor, but so far they’re not going to stop it.”

From 1980 to 2015, hot carcass weights have increased an average of 5.18 lb. per year, and Pritchard expects that to continue.

What does that mean for those who ultimately buy beef products?

“Consumers have our attention,” said Pritchard, noting that the cattle community has responded to quality assurance, food safety and animal welfare issues. “Are we doing anything about size?”

Yet economic signals say to keep making them bigger.

“We keep worrying more about this,” he said. Feeders want to do what’s best for everyone, “but right now we don’t have a price structure system that’ll encourage us to do that.”

The forums, hosted in Grand Island, Neb., and Amarillo, Texas, were co-sponsored by Micronutrients, Feedlot magazine, Zoetis, Roto-mix and Certified Angus Beef LLC (CAB). To view presentations and summary information, visit www.feedingqualityforum.com.

Editor’s Note: Miranda Reiman is the assistant director of industry information for Certified Angus Beef LLC.