Genetic Progress Increases Marketability

In search of the ‘perfect’ cow, Larsons make continual adjustments every day.

An unanswered prayer led Dan Larson back to the ranch. He and wife Becky stepped away from their dream life of horse training for a new calling — to build the best Angus herd they could.

Economics and a newfound passion brought on years of studying genetics and the Angus Journal, helping Larson Angus Ranch of Sharon Springs, Kan., build to 800 cows. The Larsons have been raising cattle since 2007, with the help of their son Brady along with his wife, Kyla, bringing up the fifth generation on the land.

Cow work, genetic improvements and breeding plans are on the table for hours because building the perfect cow takes continual adjustments. The Larsons are making moves that bring their families and customers closer to “best” every day.

“It’s one of those things that you just constantly build on,” Brady says. “You’re never going to get the perfect animal, but you just keep building on it and build on it and build on it.”

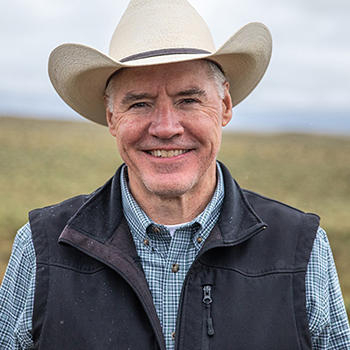

For the Larsons of Sharon Springs, Kan., cow work, genetic improvements and breeding plans are on the table for hours because building the perfect cow takes continual adjustments. Pictured are (from left) Becky, Dan, Brady and Kyla Larson. |

Their determined journey toward elusive perfection helped Larson Angus Ranch earn the Certified Angus Beef (CAB) 2022 Seedstock Commitment to Excellence award presented at the brand’s Annual Conference Sept. 22 in Phoenix, Ariz.

Spanning rough, rocky terrain along Ladder Creek, the ranch fills a niche next to farm country.

“We’re turning grass pastures that can’t be farmed into a high-quality protein source,” Dan says. “We can count on our Angus cows in this region. They work hard for us for 10 or 12 years and produce calves that have a lot of vigor.”

The Larsons like medium-frame cows with moderate milk production, good udders, calving ease and sound feet to travel. Fertility and carcass merit are non-negotiable.

They adopted artificial insemination (AI) in 1989 and within a few years started using embryo transfer (ET). That inspired Brady to pick up custom AI through ABS Global to keep him even busier during breeding season.

This year, they put in 150 embryos and, as usual, allowed cows one chance with timed AI. Whatever doesn’t stick gets another chance with the turnout bull.

“We don’t do it on a huge scale compared to other people,” Dan says, but ET work figures into most of the 100 bulls they sell each March. “This really helps us speed up genetic progress.”

The Larsons have the same priorities as their customers. Only the top bulls make the annual sale, and the best heifers become replacements while they finish the other 600 in their own feedyard to market through U.S. Premium Beef (USPB).

“Our customer base is not just selling calves at weaning, though some of them do,” Brady says. “We’ve got a lot of customers that come to us because they want to put their cattle on a grid and make extra money.”

“Our goal was to get 100% Choice, and years ago we got to that,” Dan says. “Then we tried for 100% CAB, and we reached that goal. Now we’re feeding groups of cattle that grade nearly 80% Prime and dress at 64%.”

Hitting the mark means the cattle have to excel across all expected progeny differences (EPDs) and look good doing it, Brady adds. It’s a balancing act to dance among the relevant traits.

Brady and Kyla hope to pass that way of thinking on to their four kids, sustaining and improving the water, grass and cattle so that each day they’re getting better.

Whether riding along in the side-by-side to check cows, water or put out minerals, the kids are learning by example.

“Sometimes I wonder how far we’d be if ranching had been my plan A,” Dan says.

His sights are always on the future, looking for better ways. With his family and that outlook, they’ll keep improving their best.

Editor’s note: Morgan Boecker is the producer communications manager at Certified Angus Beef.