|

Recognized for Giving it Their All

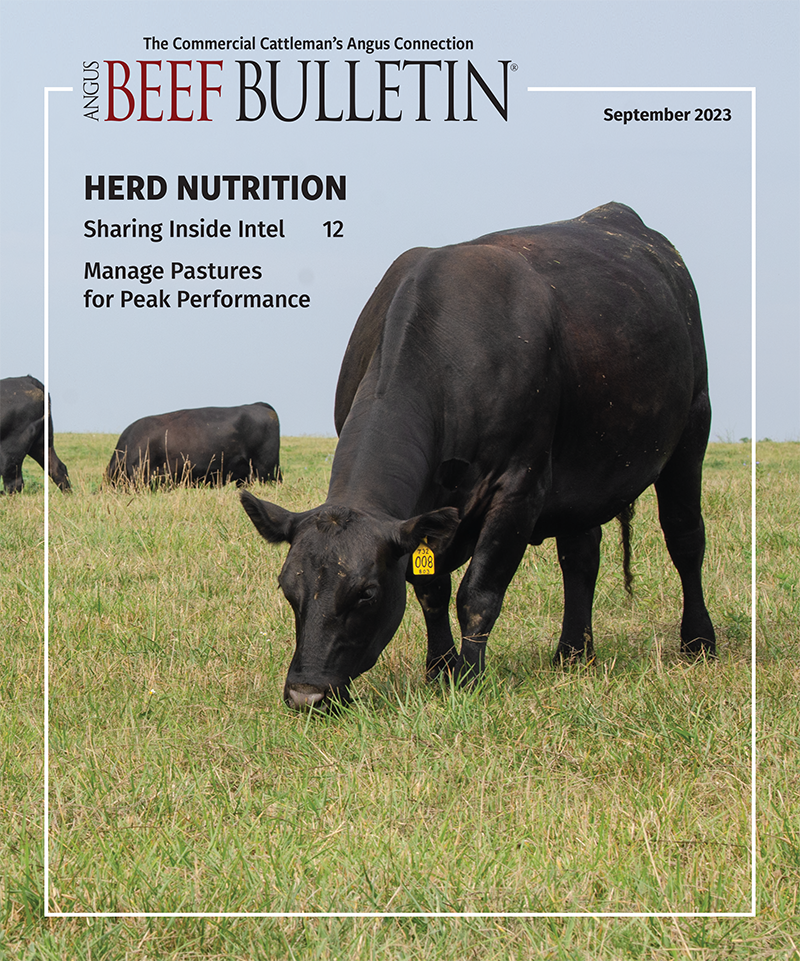

Nebraska ranch receives CAB Commercial Commitment to Excellence Award.

Some progress can be seen: replacing old barns with new ones, buying a hydraulic chute or those first calves after investing in genetics. Other progress is invisible because it happens internally, in the way you think. Both are a necessity on the Guide Rock, Neb., ranch where Troy Anderson manages a commercial Angus herd and small grower yard.

His focus is clear: maternal cows that thrive in this environment, big calves that will grade premium-Choice and Prime. His approach includes respect for his livestock, people and land. For all that and more, Anderson Cattle was honored with the 2023 Certified Angus Beef (CAB) Commercial Commitment to Excellence Award. Troy, son Zane, and parents Roy and Rosemary received the award in September at the CAB Annual Conference in Las Vegas.

Anderson Cattle was honored with the 2023 CAB Commercial Commitment to Excellence Award during CAB’s Annual Conference in September. Pictured are (back, from left) Roy, Troy, (front, from left) Rosemary and Zane Anderson. |

When Roy first moved to Nebraska in 1963, he found run-down fences, eroded farm ground and a dream that transformed it with terraces, trees and new fences. The days were long and the work physically exhausting. Roy and Rosemary balanced raising a family and farming wheat, milo and silage while gradually growing their herd.

“There’s always been the desire to raise good cattle and do a good job with the cattle we have,” Troy says. Over the years, they continued to seek better genetics. Troy looks for Targeting the BrandTM logos in bull sale books.

“Targeting the Brand tells me a bull has the genetics to produce a higher percentage of calves that qualify for CAB,” Troy says. That’s his target, too.

It just made sense to build a yard to grow and finish calves at the ranch. Since 2015 Troy has fed and finished home-raised, purchased or customer cattle in his 850-head feedyard. All are marketed on a quality-based grid.

As soon as he gets the carcass data back, he’s matching sires to individual progeny carcass values to see if the sires will be used again next breeding season. Data and technology open doors to improvement.

“We’re bottom-line driven,” Troy notes. “If we can get an extra $6 per hundredweight, that’s $50 to $60 a head. That can be the difference between making money or not on a set of calves, especially with the things we’ve gone through the last few years in the cattle industry.”

In May 2023, Anderson’s calves hit 88% Choice and Prime with 44% CAB. The few Select grades usually trace back to some problem in a calf’s life, Troy says.

“Harvesting more CAB qualifiers not only gives us more profit, but it helps consumers feel better about beef,” he says. “It also makes me feel better about our cattle, knowing that we’re producing beef that people want and enjoy.”

Troy finished his 850-head grow yard in 2015 and has filled it with home-raised, purchased and customer cattle ever since. |

Additionally, consumers can feel better because the cattle raised according to Beef Quality Assurance (BQA) guidelines relate not only to product in the grocery meatcase, but to the entire herd.

That extends to Troy taking care of his land in an environment that tests him often.

“We put in miles and miles of crossfence and several miles of water lines to tanks,” he says of his fencing career after moving home in 2001.

The new system distributed the cows’ grazing, resulting in better grass. It makes life a lot easier for herd and pasture, especially during a drought, he adds. Cows will graze more areas of the pasture when they have access to fresh water.

They artificially inseminated 100 heifers and 150 cows last spring, a herd that’s dwindled in the face of too many consecutive dry years.

Water lines flow across 600 feet (ft.)-1,000 ft. of surface to get water to cows lucky enough to be on grass. Others were fed longer and drylotted well into summer.

The barbed wire balls that greet you at the drive are remnants of a fire that burned across the ranch Jan. 14, 2021. It’s a reminder of the hard times the Andersons have survived. |

“It’s a testament to Angus cows and careful management,” Troy says. “We’ve pushed them for efficiency, but upped our mineral program to make up for the differences.”

Even though the days are long, memories of progress bring a smile. It isn’t easy passing the reins to the next generation, but Troy says his parents have been accommodating to let him make decisions and learn from them.

Cattle may determine what’s on today’s to-do list, but people are the heart of the operation.

It takes the same firm yet gentle hand to be a stockman and a dad. Lessons Troy learned the hard way guide him as a father today when he has Zane in tow.

“I like to help sort cattle because you can learn a lot about them,” Zane says. “Dad taught me to be calm around livestock because they can sense you. So, if you’re angry or happy, they can sense that.”

“To have Zane out there wanting to learn, it means the world to me thinking I’m raising someone who may help move the industry forward,” Troy says.

Everything they accomplish, they accomplish as a family.

“We have lived here 50-some years now,” Roy says, “and we’ve got everything situated about the way we want it.”

Still, the next 10 years will only build on successes as they give everything they have to get better.

Editor’s note: Morgan Boecker is the senior manager of producer communications for Certified Angus Beef LLC.